With the improvement of the treatment rate of domestic sewage and industrial wastewater, the sludge production is increasing day by day. Due to the high water content of sludge and poor dewatering performance, the cost of sludge follow-up treatment increases sharply. Therefore, how to improve the dewatering performance of sludge, reduce the volume of sludge and reduce the cost of sludge follow-up treatment has become an important research topic. The pretreatment of sludge by physical, chemical or biological methods can change the physical properties and chemical composition of sludge floc, destroy the colloidal structure of sludge, reduce the affinity between sludge and water, and improve the quality of sludge. Dehydration properties. As a chemical conditioning method, the addition of chemical agents is widely used because of its simple operation and low cost.

The sludge dehydrating agents commonly used in the market now are polyacrylamide, ferric chloride, lime and so on. However, the use of these agents not only can not achieve deep dehydration of sludge, but also a large amount. At the same time, the long-term use of these chemicals will also cause a certain corrosion of sludge dewatering equipment, reducing the cost of equipment. In response to the above problems, Works Chemical has successfully developed a new sludge dehydrating agent through continuous independent research and development, which can effectively replace the common sludge dehydrating agent on the market.

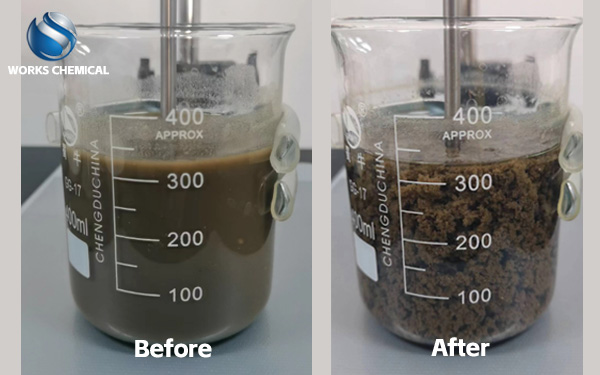

Next, Works Chemical will introduce to you, what are the functions of the sludge dewatering agent independently developed by Works Chemical? Why can it replace the traditional sludge dehydrant? Sludge dehydrating agent is a kind of chemical agent which can change the surface structure of sludge, reduce the solid surface load of sludge, reduce the specific surface area of sludge and destroy the structure of bacteria. The main components are inorganic compounds, sludge surface structure modifier, degreaser, wall breaking agent, sludge surface treatment agent, sludge stripping agent and so on.

The role of sludge dewatering agent:

1. Sludge moisture content can be reduced to 40%-60%.

2. the use of plate and frame filter press can effectively improve productivity, mud press efficiency increased by 100%-- 500%, reduce the mud cycle.

3. effectively reduce the filter cloth replacement frequency.

4. add a small amount, no need to add lime.