In the process of leather production, a large amount of wastewater will be generated after chromium tanning and retanning processes using chromium tanning agents. These wastewater in the treatment process will produce sludge and residue, namely leather sludge. Leather sludge not only contains a lot of water, but also often contains toxic and harmful substances such as heavy metal chromium, which brings great challenges to environmental treatment. In order to effectively treat leather sludge, sludge enhancer, as a highly efficient chemical agent, is gradually being widely used in this field.

Characteristics and treatment difficulties of leather sludge

Leather sludge has the characteristics of high moisture content, high viscosity, and difficult to dehydrate. Because most of its particles have a certain charge, and contain a large number of colloidal substances and microbial cells, it is difficult to aggregate and precipitate between the sludge particles, and the dehydration performance is very poor. The traditional dehydration method is often difficult to achieve the ideal dehydration effect, and the treatment cost is high and the efficiency is low.

Mechanism of action of sludge synergists

Sludge enhancer is a chemical agent specially used to improve the dewatering performance of sludge. It usually contains a variety of complex ingredients, such as inorganic compounds, sludge surface structure modifier, degreaser, wall breaking agent, sludge surface treatment agent, sludge stripping agent and so on. Together, these components can significantly change the surface structure and properties of the sludge, thus achieving a better dehydration effect.

Specifically, the mechanism of action of sludge synergists mainly includes the following aspects:

Change the surface properties of the sludge: the sludge synergist can change the surface charge distribution and hydrophobicity of the sludge particles, making it easier to aggregate and precipitate between the sludge particles.

Damage the colloidal structure of the sludge: the sludge synergist can destroy the colloidal structure of the sludge, reduce the viscosity of the sludge, and make the sludge particles easier to separate and dehydrate.

Damage microbial cell structure: Sludge enhancers can destroy the microbial cell structure in the sludge and release the bound water in the cell, which is often difficult to remove in the conventional dehydration process.

Form a more stable bond: The sludge synergist is able to form a more stable bond with the water molecules in the sludge, thereby reducing the freedom of the water molecules and helping to separate more water from the sludge during the dehydration process.

Application of sludge enhancer in leather sludge treatment

The application of sludge enhancer in the treatment of leather sludge is remarkable. By adding an appropriate amount of sludge enhancer, the dewatering performance of leather sludge can be significantly improved, making it easier to dehydrate by mechanical dewatering equipment. Specifically, the application of sludge enhancer in leather sludge treatment mainly includes the following steps:

Sludge pretreatment: The leather sludge is pretreated to remove large impurities and foreign bodies for subsequent treatment.

Adding sludge enhancer: the appropriate amount of sludge enhancer is added to the pre-treated leather sludge, and is fully mixed to make the sludge enhancer fully contact with the sludge particles and play a role.

Mechanical dewatering: the leather sludge after adding the sludge enhancer is sent to the mechanical dewatering equipment (such as plate and frame filter press, belt filter press, etc.) for dewatering. Under the action of mechanical force, the sludge synergist is fully mixed with the sludge and plays a role, making the sludge particles more closely combined to form a sludge cake that is easier to dehydrate.

Follow-up treatment: follow-up treatment of the dehydrated sludge cake, such as incineration, brick making, composting, etc. As the moisture content of the dehydrated sludge is greatly reduced, the volume is reduced, which is convenient for subsequent transportation, storage and disposal.

Four. Advantages of sludge synergist application

Compared with traditional dewatering methods, the use of sludge enhancers to treat leather sludge has the following advantages:

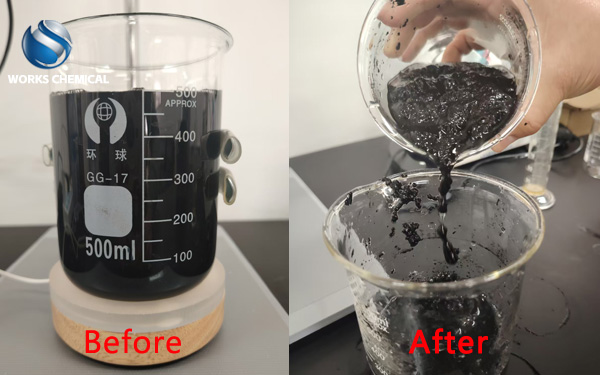

Dehydration effect is significant: sludge synergist can significantly reduce the moisture content of leather sludge, usually can reduce the moisture content of sludge from more than 90% to 40%-60%, to achieve the reduction of sludge treatment.

High treatment efficiency: sludge synergist can significantly improve the dewatering efficiency of leather sludge, shorten the dewatering time, thereby reducing the running time and energy consumption of dewatering equipment.

Low treatment cost: Because the sludge enhancer has the advantages of small dosage and low cost, the use of sludge enhancer to treat leather sludge can reduce the treatment cost.

Good environmental protection effect: the moisture content of the leather sludge after the treatment of the sludge enhancer is greatly reduced, the volume and weight of the sludge is reduced, and the environmental pollution risk in the transportation and storage process is reduced. At the same time, the dehydrated sludge cake is easier to carry out follow-up treatment, such as incineration, brick making, composting, etc., which helps to realize the resource utilization of the sludge.

Conclusion

The application effect of sludge synergist in leather sludge treatment is remarkable, and it has the advantages of remarkable dewatering effect, high treatment efficiency, low treatment cost and good environmental protection effect. With the increasingly strict environmental regulations and the continuous progress of sludge treatment technology, sludge synergists will play an increasingly important role in the field of leather sludge treatment. In the future, with the continuous innovation of technology and the continuous accumulation of application experience, the performance and application effect of sludge synergists will be further improved and optimized.