In the process of pharmaceutical production, the production of sludge is inevitable. These sludge not only contain a large amount of water and organic matter, but also may carry pathogens and drug residues, posing a potential threat to the environment and human health. Therefore, how to treat medical sludge efficiently and safely has become an important topic in the pharmaceutical industry. As an effective auxiliary material for sludge treatment, sludge enhancer plays an important role in medical sludge treatment.

Characteristics of pharmaceutical sludge

Pharmaceutical sludge usually has the following characteristics:

High moisture content: Pharmaceutical sludge often contains high moisture, which increases the difficulty and cost of treatment.

High organic content: sludge contains a large number of organic matter, including drug residues, microorganisms, etc., which need to be effectively treated.

May carry pathogens: Medical sludge may contain various pathogens, such as bacteria, viruses, etc., which need to be strictly disinfected.

Role of sludge synergists

Sludge enhancer is a chemical agent that can significantly improve sludge dewatering performance. In medical sludge treatment, sludge synergists mainly play the following roles:

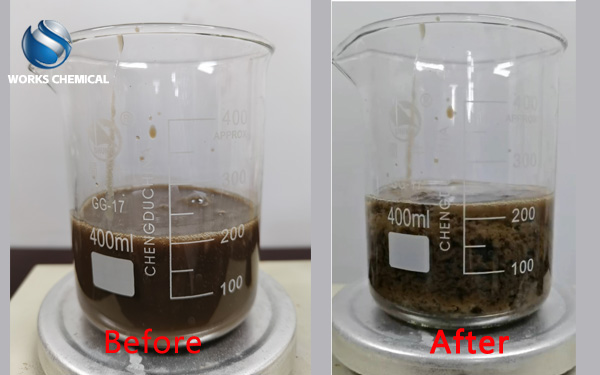

Improve dehydration efficiency: sludge enhancer can change the surface properties of sludge particles, such as charge distribution and hydrophobicity, so that the accumulation and precipitation between sludge particles are more likely to occur, thereby improving the dehydration efficiency.

Reduce moisture content: By improving the dewatering performance of the sludge, the sludge synergist can significantly reduce the moisture content of the sludge, reduce the volume and weight of the sludge, and reduce the treatment cost.

Improve sludge properties: sludge synergists can also destroy the microbial cell structure in the sludge, release the bound water in the cell, and reduce the viscosity of the sludge, making the sludge easier to handle.

Application of medical sludge treatment

In medical sludge treatment, sludge synergists are usually used in combination with mechanical dewatering equipment (such as plate and frame filter press, belt filter press, etc.). The specific processing process is as follows:

Sludge pretreatment: First of all, the medical sludge is pretreated, such as adjusting the pH value, adding disinfectants, etc., to kill pathogens and remove some organic matter.

Add sludge enhancer: Add an appropriate amount of sludge enhancer into the pre-treated sludge, and fully mix evenly.

Mechanical dehydration: the mixed sludge is sent to the mechanical dewatering equipment for dewatering treatment. In the dewatering process, the sludge synergist can play a significant role in improving the dewatering efficiency and reducing the moisture content.

Follow-up treatment: The dehydrated sludge cake needs further treatment, such as incineration, landfill or resource utilization. According to the nature of sludge and treatment requirements to choose the appropriate follow-up treatment method.

Precautions

When using sludge synergists to treat medical sludge, the following points need to be noted:

Select the right sludge enhancer: Select the right sludge enhancer according to the nature of the sludge and treatment requirements to ensure the treatment effect and economy.

Control dosage: The dosage of sludge enhancer should be adjusted according to the nature of the sludge and the performance of the treatment equipment. Too much or too little dosage may affect the treatment effect.

Monitoring treatment effect: In the process of use, the dewatering effect and water content of the sludge should be regularly monitored to ensure the effectiveness of the sludge synergist.

Compliance with environmental regulations: When selecting and using sludge enhancers, relevant environmental regulations and standards should be complied with to ensure that the treated sludge meets environmental requirements.