Leather sludge, as a typical hazardous waste generated by the tanning industry, has long faced the predicament of high treatment costs and great difficulty in resource utilization due to its high moisture content, complex organic composition and heavy metal residue characteristics. The emergence of sludge enhancers has provided an innovative solution to this problem.

I. Pain Points in the Treatment of Leather Sludge

Component complexity

Leather sludge contains a large amount of protein, oil, chromium tanning agent (trivalent chromium) and surfactant residues, which leads to high sludge viscosity and poor dewatering performance. Even after traditional mechanical dewatering, the moisture content is still as high as over 80%.

Heavy metal risk

Although chromium exists in the form of trivalent chromium, it may transform into hexavalent chromium, which is more toxic, under specific conditions. Therefore, strict control is required during the handling process.

Resource Utilization bottleneck

High organic matter content could have been an advantage for resource utilization, but traditional treatment methods are difficult to effectively separate pollutants from useful components, resulting in sludge being ultimately landfilled or incinerated.

Ii. Mechanism of Action of Sludge Enhancer

The sludge enhancer, through the synergistic effect of multiple components, specifically improves the treatment performance of leather sludge:

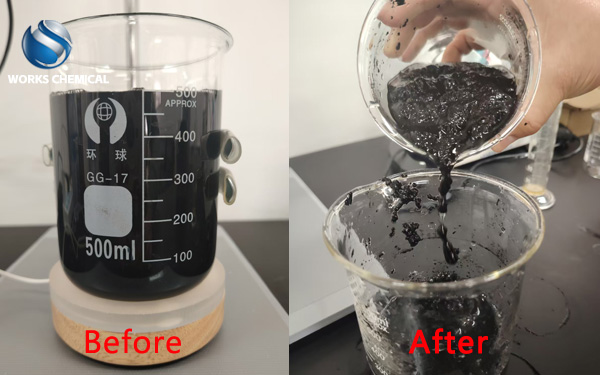

Gel breaking and modification

It contains special surfactants, which can destroy the protein-oil cementation structure in sludge, release bound water and reduce the specific resistance of sludge.

Heavy metal passivation

Chelating agents form stable complexes with chromium ions, reducing the leaching concentration of chromium and meeting the standards for landfill or resource utilization.

Microbial activation

Adding salt-tolerant bacterial strains and nutrients can promote the degradation of organic matter during the sludge composting process and simultaneously achieve the biological fixation of heavy metals.

Iii. Application Scenarios and Effect Verification

Mechanical dehydration optimization

After a certain leather processing enterprise applied the enhancer, the processing cycle of the plate and frame filter press was shortened, the moisture content of the sludge dropped from 82% to 55%, and the cost of treating one ton of sludge was reduced.

Synergistic anaerobic digestion

In the anaerobic digestion system of sludge, enhancers promote the hydrolysis of organic matter, increase methane production, and at the same time reduce the ammonia nitrogen concentration in the digestion liquid, thereby reducing the risk of system inhibition.

Expansion of Resource Utilization Paths

Sludge treated with enhancers can be processed into fuel particles through pyrolysis technology, thereby increasing its calorific value. Or it can be used as raw material for building materials, and the leaching of heavy metals meets the standards.

Iv. Technical and Economic Analysis

Take a factory that processes 100 tons of leather sludge per day as an example:

Direct cost: The cost of adding the enhancer is per ton of sludge, accounting for 15% of the total treatment cost.

Improved benefits: Due to the reduction in moisture content, transportation costs decrease; The revenue from resource-based products has increased.

Payback period: The equipment renovation and chemical input can be recovered within 18 months through cost savings and increased returns.

V. Industry Application Prospects

With the tightening of environmental protection policies, the application of sludge enhancers in the leather industry will show the following trends:

Customized development: Develop specialized enhancers for different tanning processes (such as chrome tanning and chromium-free tanning) to enhance processing accuracy.

Low-carbon upgrade: By integrating carbon capture technology, sludge treatment is coordinated with greenhouse gas reduction to contribute to the goal of carbon neutrality.

Intelligent control and management: By using sensors to monitor the properties of sludge in real time and dynamically adjust the dosage of enhancers, precise governance can be achieved.

The sludge enhancer not only provides a technological breakthrough for the treatment of leather sludge, but also promotes the transformation of the industry from "end-of-pipe treatment" to "resource recycling". In the future, with the integrated innovation of materials science and biotechnology, sludge enhancers are expected to become the core driving force for the green development of the leather industry.