During the rapid development of the leather industry, the environmental problems hidden behind it have become increasingly severe, especially the treatment of leather sludge, which has become a huge obstacle to the industry's development. Leather sludge is complex in composition and highly harmful. Traditional treatment methods are not very effective. However, sludge enhancers, with their innovative technology and outstanding performance, have become the key tool to solve the problem of deep dewatering of leather sludge.

I. The Complex Characteristics and Dewatering Dilemma of Leather Sludge

Leather production involves multiple processes such as tanning, dyeing and rinsing, and each stage generates a large amount of sludge with special properties. The extensive use of chromium salts during the tanning process results in a large amount of heavy metal chromium in leather sludge. Among them, hexavalent chromium, which is highly toxic, if not properly handled and enters the environment, will cause long-term and difficult-to-remediate pollution to soil and water sources, seriously threatening the security of the ecosystem and human health. The various organic dyes brought about by the dyeing process not only endow the sludge with rich colors but also have the characteristics of complex structure and difficulty in degradation. The harmful substances in these dyes, when remaining in the environment, will have a negative impact on biodiversity.

From the perspective of physical properties, the moisture content of leather sludge is extremely high, usually ranging from 95% to 99%. The organic substances such as proteins, oils, and fibers within it are entangled with each other, forming a highly viscous colloidal structure. This structure is like a dense net, firmly confining water within it, making it difficult for ordinary dewatering methods and chemicals to destroy its structure and achieving effective separation of water from sludge particles. Traditional mechanical dewatering methods, such as belt filter press and centrifugal dewatering, not only have low efficiency when treating leather sludge, but also the moisture content of the dewatered sludge cake is still as high as 70% - 80%, which cannot meet the requirements of subsequent disposal and resource utilization. Moreover, during the dewatering process, leather sludge is prone to clogging the dewatering equipment, leading to frequent equipment malfunctions and high maintenance costs, further exacerbating the predicament of leather sludge treatment.

Ii. The Working Principle and Technical Advantages of Sludge Enhancers

Sludge enhancer is a compound agent specially developed for complex industrial sludge. Its unique formula and mechanism of action enable it to precisely address the characteristics of leather sludge and become an effective tool for deep dewatering. This enhancer is mainly composed of multiple components such as heavy metal chelating agents, cell wall disruptors, surfactants, degreasing agents and high-molecular flocculants. These components work in synergy to improve the dewatering performance of leather sludge from multiple dimensions.

Heavy metal chelating agents play a crucial role in the treatment of leather sludge. They can specifically combine with heavy metals such as chromium ions in the sludge to form stable and insoluble chelates. This combination not only reduces the mobility and bioavailability of heavy metals, effectively lowering the risk of heavy metal pollution in subsequent treatment processes, but also avoids the interference of heavy metals with other dewatering agents, ensuring the smooth progress of the entire dewatering process.

Polymer flocculants adsorb sludge particles through the active groups on their molecular chains, forming bridging connections between the particles, which promotes the rapid aggregation and coagulation of originally fine and dispersed sludge particles into large and dense flocs. These flocs have excellent sedimentation and filtration performance. Under the action of dewatering equipment, they can achieve efficient solid-liquid separation and significantly improve the dewatering efficiency.

Iii. The remarkable Effects of Sludge enhancers in treating Leather sludge

(1) Deep dewatering to achieve efficient sludge reduction

When used in combination with suitable dewatering equipment (such as plate and frame filter presses), the sludge enhancer demonstrates outstanding performance in the deep dewatering of leather sludge. Practical application data show that the moisture content of leather sludge can be significantly reduced from over 90% to 40% - 50%, and even reach a lower level under certain optimized conditions. The volume of the dehydrated mud cake is significantly reduced. Compared with the traditional treatment method, the sludge reduction effect can reach 60% - 70%. This not only significantly reduces the subsequent transportation and disposal costs of sludge, but also lessens the environmental pressure caused by sludge landfill or incineration, thus easing the environmental protection burden on leather enterprises.

(2) Reduce the content of harmful substances and decrease the risk of secondary pollution

During the dewatering process, the sludge enhancer effectively reduces the content of harmful substances in the sludge cake through the synergistic effect of multiple components. After treatment, the leaching concentration of heavy metals such as hexavalent chromium in the mud cake is significantly reduced, far below the relevant national environmental protection standards, greatly reducing the risk of heavy metal pollution to soil and water bodies. Meanwhile, pollutants such as organic dyes are effectively encapsulated in the flocs, significantly reducing the possibility of their release into the environment during subsequent disposal, and greatly lowering the risk of secondary pollution, which meets the current strict environmental protection requirements.

(3) Enhance dehydration efficiency and reduce the operating costs of enterprises

After the use of sludge enhancers, the dewatering performance of leather sludge has been significantly improved, and the dewatering cycle has been significantly shortened. The traditional method for treating leather sludge may take several hours or even longer for a single dewatering process. However, after adding sludge enhancers, the dewatering time can be shortened to 1-2 hours. This not only enhances the utilization efficiency of the dehydration equipment, but also reduces its operating time and energy consumption. Meanwhile, as the sludge enhancer can form large, structurally stable flocs, it reduces the clogging of filter cloth, lowers the frequency of equipment cleaning and maintenance, and extends the service life of the equipment, thereby effectively reducing the operating costs of leather enterprises and improving their economic benefits.

Iv. Practical Application Cases

A well-known large-scale leather products manufacturing enterprise generates as much as 80 tons of leather sludge every day. In the past, this enterprise used traditional lime and polyacrylamide for sludge conditioning and combined with belt filter presses for dewatering treatment, but the effect was not ideal. After dehydration, the moisture content of the mud cake remains at around 75% for a long time, and the chromium content in the mud cake often exceeds the standard. Enterprises not only face high processing costs but also bear huge environmental protection pressure.

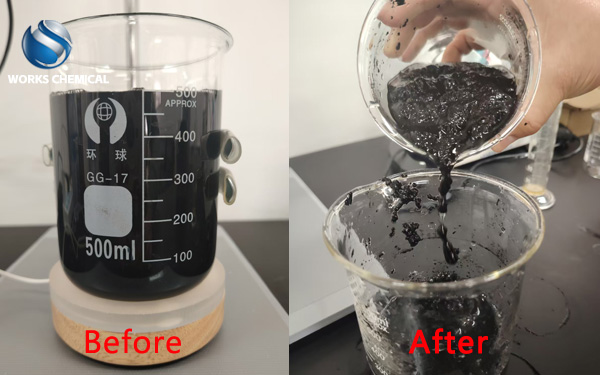

After introducing the sludge enhancer, the enterprise optimized and adjusted the treatment process. Firstly, through the laboratory beaker test, the optimal dosage and reaction time of the sludge enhancer were determined. Then, an appropriate amount of sludge enhancer is thoroughly mixed and reacted with the leather sludge in the stirring tank to ensure that the agent fully contacts the sludge particles. Finally, the conditioned sludge is sent to the plate and frame filter press for dewatering treatment.

After a period of operation, the treatment effect is very remarkable. The moisture content of the mud cake was successfully reduced to 45%, with a significant reduction in sludge volume and a substantial decrease in transportation and disposal costs. Meanwhile, the chromium content in the mud cake also meets the relevant environmental protection standards, and the enterprise has successfully passed the inspection of the environmental protection department. In addition, due to the improvement in dewatering efficiency, the operating time of the equipment has been shortened, and the maintenance frequency has decreased. The enterprise saves millions of yuan in equipment maintenance costs and sludge disposal costs every year, achieving a win-win situation in both economic and environmental benefits.

V. Conclusion

In the highly challenging field of deep dewatering of leather sludge, sludge enhancers, with their unique principle of action, significant treatment advantages and good practical application effects, have become powerful weapons to solve the problem. It not only effectively solves the problems of difficult dewatering and heavy pollution of leather sludge, but also provides reliable technical support for leather enterprises to reduce costs and achieve sustainable development. With the continuous improvement of environmental protection requirements and the sustained innovation of technology, sludge enhancers are expected to be more widely applied and promoted in the leather industry, driving the treatment of leather sludge towards a new stage that is more efficient, environmentally friendly and sustainable, and safeguarding the green development of the leather industry.